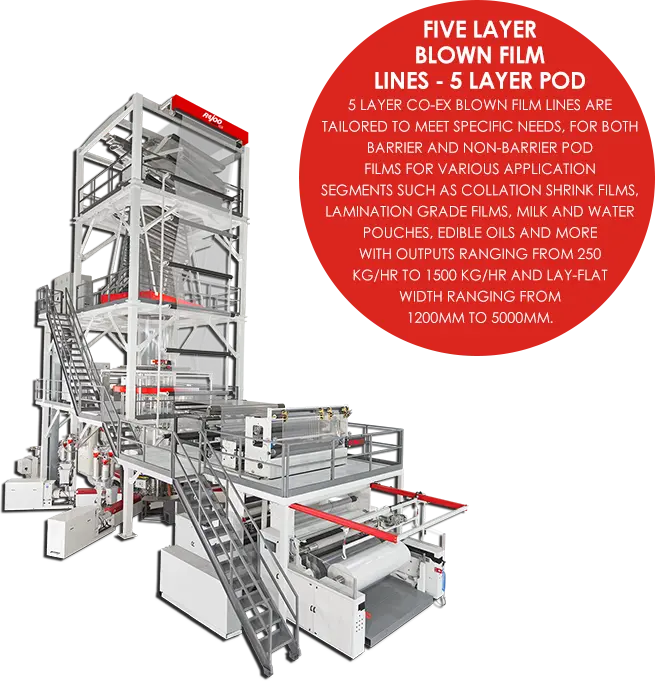

Our five layer pods delivers innovation and excellence in plastic processing machinery converge. Our cutting-edge five layer pods, also known as five-layer blown film lines, cater to the diverse needs of various industries. Let’s explore what makes our five layer pods the ultimate choice for your production needs.

A five layer pod, or five layer blown film line, is an advanced manufacturing system designed to produce high-quality, multi-layer films used across various applications such as packaging, lamination, and barrier films. These lines are engineered for efficiency, versatility, and superior film quality.

Our Pentafoil – five-layer blown film lines incorporate advanced technology and precision engineering. Featuring direct-coupled motors, fluid temperature controllers, and a unique Cylindrical Spiral Die (CSD) system, our five-layer pods offer optimal performance and exceptional film quality. Designed using computerized design and 3D simulation, these systems ensure excellent thickness distribution and minimal wastage.

1. Versatility: Suitable for various applications like collation shrink films, milk pouches, and edible oil packaging.

2. Efficiency: Outputs ranging from 250 kg/hr to 1500 kg/hr with lay-flat widths from 1200mm to 5000mm.

3. Advanced Features: Automation features such as integrated material conveying, GSM control, and automatic thickness control.

Ready to elevate your production capabilities?

Contact Rajoo Engineers Ltd. today to learn more about our five-layer pods and how they can transform your business.